Welcome to Shenzhen Chenqiyuan Technology Co., Ltd. Official website!

National Service Hotline

+86-755-61196877

Categories:In addition to static

KP503ADJ 4.5th generation mechanical and intelligent ion wind bar is the latest development and production of Kappa company to eliminate static electricity on the surface of the stick-type device.

KP503ADJ 4.5th generation mechanical and intelligent ion wind bar uses DC high-voltage power supply, adopts special alloy electrode, and acts on the electrode needle through positive and negative DC high voltage alternately, that is, DC high voltage source adopts AC implementation mode to generate corona discharge and air molecules Ionization generates a large amount of positive and negative air ions, and it is transported to the surface of the electrostatic object to neutralize the positive and negative electrostatic charges to achieve the purpose of efficiently and reliably eliminating static electricity on the surface of the object.

product description

KP503ADJ 4.5th generation mechanical and intelligent ion wind bar is the latest development and production of Kappa company to eliminate static electricity on the surface of the stick-type device.

KP503ADJ 4.5th generation mechanical and intelligent ion wind bar uses DC high-voltage power supply, adopts special alloy electrode, and acts on the electrode needle through positive and negative DC high voltage alternately, that is, DC high voltage source adopts AC implementation to generate corona discharge and air molecules Ionization generates a large amount of positive and negative air ions, and it is transported to the surface of the electrostatic object to neutralize the positive and negative electrostatic charges to achieve the purpose of efficiently and reliably eliminating static electricity on the surface of the object.

Can be widely used in electronics, plastics, chemicals, printing, textiles, optoelectronics and other industries.

Features

1, for the stick type, horizontal static eliminator.

2, using the latest patented static technology manufacturing.

3, in addition to fast speed, low balance voltage, high safety performance.

4. The LCD on the stick can display the working status of the ion stick, which is easy to use and maintain.

5, the output voltage characteristics can be adjusted for different electrostatic environment.

6, with ion, electrode needle cleaning, high pressure fault alarm function.

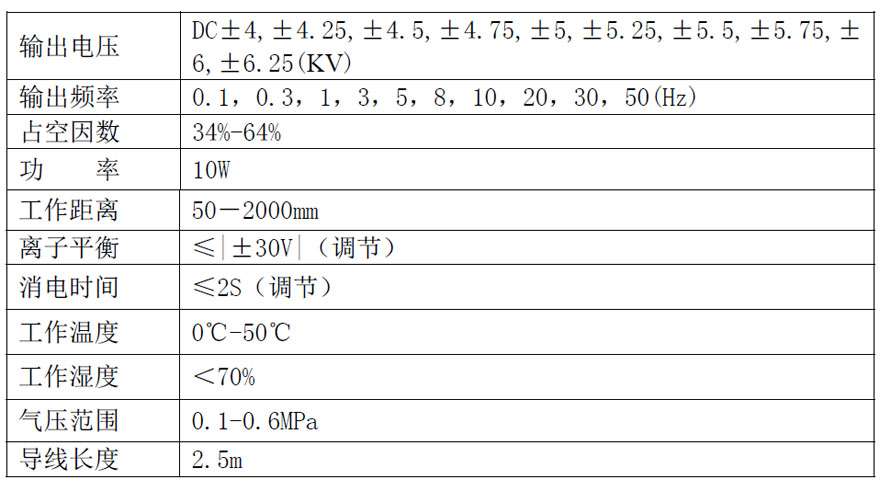

Technical Parameters

Safety instructions

1. Please read the instruction manual carefully before installing and using this equipment.

2. The entire equipment must be reliably grounded during use. Otherwise, the stick body may be burned.

3. Do not touch the electrode needle during operation of the ion rod.

4. It is difficult to use the device in a humidity environment of >70%.

5. The gas source connected to the ion bar must be clean air after filtration of moisture, grease, and fine dust.

6. It is forbidden to use this equipment in flammable and explosive environments.

7, internal maintenance and repair must be carried out by professionals.

Functional instructions

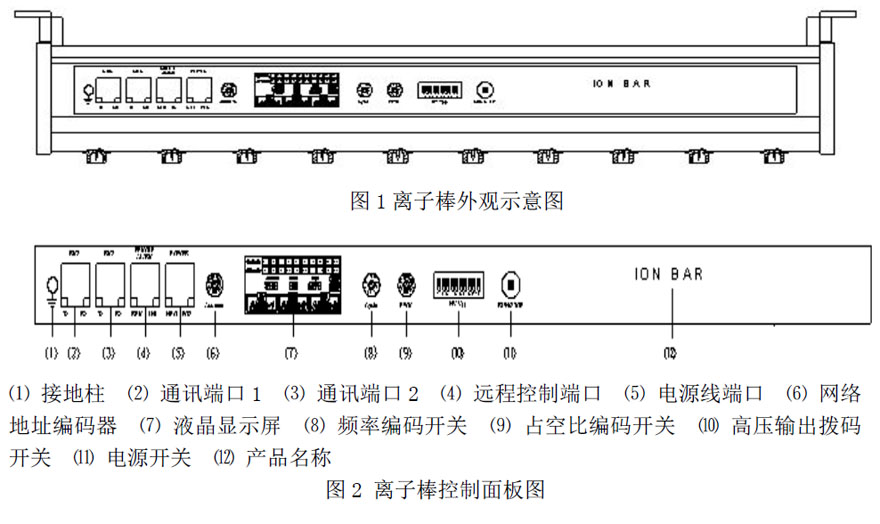

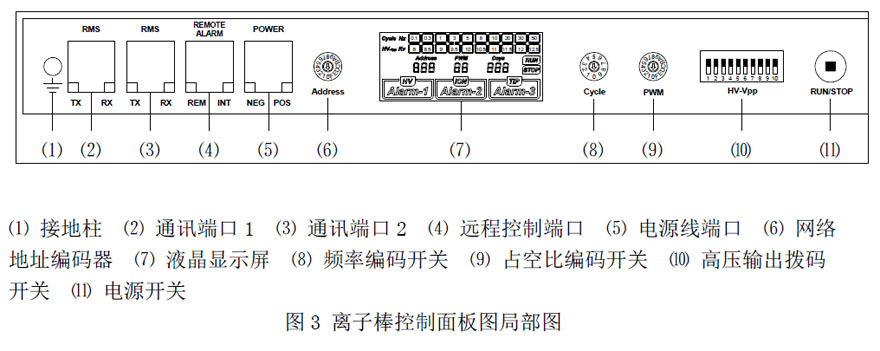

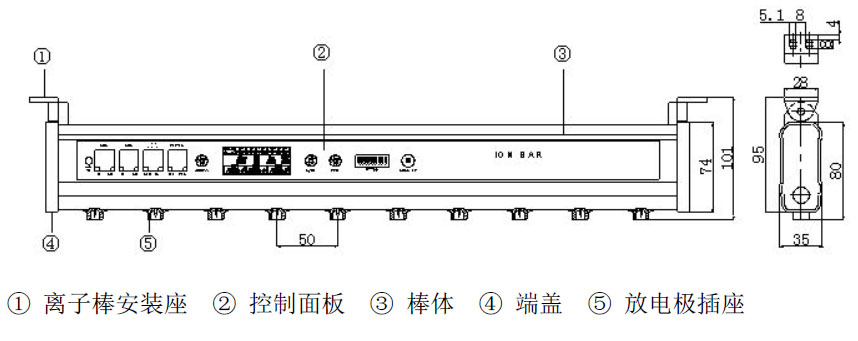

1. Output voltage level adjustment: The output high voltage characteristics can be adjusted through the control panel shown in Figure 3 on the ion bar housing of Figure 1. When toggling the high-voltage output dip switch shown in Figure 3, HV-Vpp, the corresponding high-voltage output value will be displayed on the LCD screen shown in Figure 3.

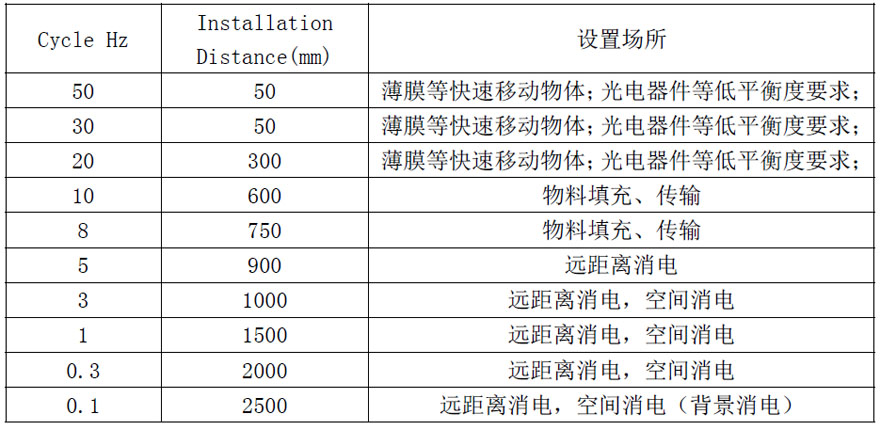

2. Output frequency adjustment: When you toggle the frequency coding switch shown in Figure 3 - Cycle Hz, the corresponding positive and negative high voltage alternating frequency values will be displayed on the LCD screen shown in Figure 3.

3. Output duty cycle adjustment: When toggling the duty cycle coding switch shown in Figure 3 - PWM, the corresponding positive and negative high voltage duty cycle values will be displayed on the LCD screen shown in Figure 3.

4. High-voltage output failure alarm: When the high-voltage component of the ion rod is damaged or there is a high-voltage output failure due to other reasons, a high-voltage fault sound alarm, HV Alarm-1, will be issued and alarmed on the LCD screen shown in FIG. 3.

5, ion volume alarm: When the ion rod due to electrode contamination or electrode erosion passivation, the number of ions generated by a substantial reduction, will issue an ion volume sound alarm - ION Alarm-2, and alert the LCD shown in Figure 3 On the screen.

6. Electrode needle cleaning alarm: When the ion rod working time reaches the set value or because the electrode is seriously contaminated, an electrode needle cleaning sound alarm—TIP Alarm-3—will be issued, and the alarm is shown on the LCD screen shown in FIG. 3 .

7. Communication function: From figure 2, we can see that the ion bar work information can be transmitted to the PC through one RMS port on the control panel; another RMS port can realize two intelligent ion bar serial communication; it can also be connected through the REMOTE port. To the remote service controller.

8, special tips

(1) The parameter setting of the voltage output characteristic can only be performed when the ion bar is in the "STOP" key state of the power switch. After the setting is completed, press the "RUN" key of the power switch and the ion bar is in the working state.

(2) Parameter setting suggestions:

Installation and use

1, installation and use of guidance:

(1) Select the best static elimination position and install the rod and the matching power adapter firmly.

(2) Connect the ground terminal on the rod to the ground wire.

(3) Insert one end of the power cable into the socket of the power adapter and the other end into the power socket on the stick body.

(4) Connect the air source connector on the rod body to the air source generator and open the air source switch.

(5) Turn on the power switch on the stick. The switch indicator lights to show the operation of the ion bar, adjust the suitable air source pressure, transport the positive and negative air ions generated at the electrode needle, and neutralize the static electricity on the surface of the object.

2,Dimensions:

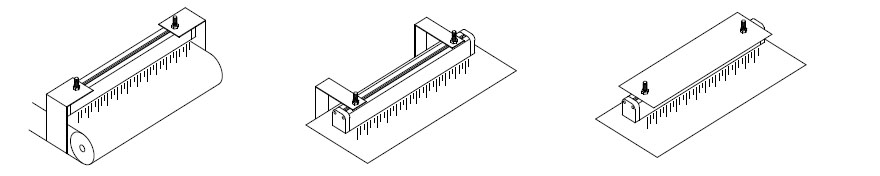

3, installation method diagram:

4, technical tips:

(1) When using ion rods, they should be placed in the work area to eliminate static electricity, and the installation angle should be perpendicular to the surface of the charged body.

(2) The ion rod discharge electrode should be away from the metal conductor and metal grounding body around the discharge electrode, and the rod body must be reliably connected to the grounding wire.

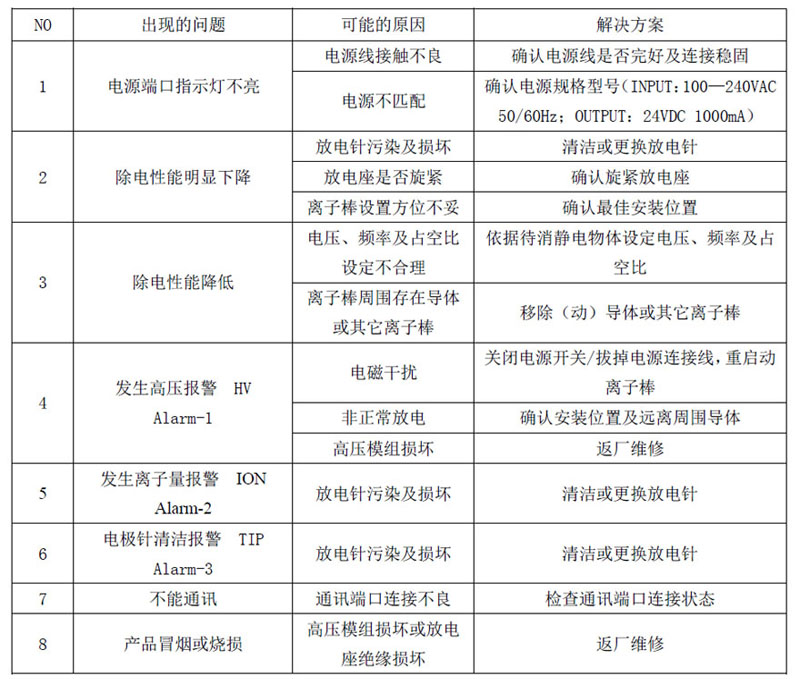

(3) Fault Solution:

maintenance

1. In order to ensure the good performance of this product, it should be cleaned and maintained in time according to the use environment and the required electrostatic protection requirements. That is, using an electrostatic brush or dustless cloth to draw anhydrous alcohol and gently remove the discharge electrode and discharge socket. The carbon deposits on the metal discharge body will obviously improve its performance.

Note:

A. It must be operated 10 minutes after the power is turned off.

B. When the ion bar is in use, when the needle tip has accumulated dust or white product, it must be cleaned. When using a matching brush can not meet the cleaning requirements, you can use a clean cloth dipped in anhydrous alcohol.

C. After cleaning, you must wait for the alcohol to completely evaporate and then work on electricity. Do not use any other organic solvents to clean the rod.

2. If the POS/NEG switch work indicator of the power plug on the stick panel is not off when it is turned on, it should be stopped and checked by professional maintenance personnel. It can be used only after the electrical performance indicator is normal.

Accessories

1. Warranty card 2, manual 3, certificate 4, mounting bracket 5, power adapter 6, power cable 7, three-core power cable

Section IX: Product Warranty and Service

1. The KP503A 5th generation intelligent ion wind bar undergoes rigorous testing and aging before leaving the factory, and its performance fully meets the relevant indicators marked in the instructions for use.

2. The Kappal brand promises to the user as follows: Within one year from the date of purchase, the company will repair or replace any parts that have been inspected by the company for defects. However, this commitment does not apply to the following situations: equipment is misused and installed; negligence during use, damage caused by accident; self-modification, disassembly, or repair by other service departments not authorized by the company. The company does not assume any obligation and the related responsibility of the product user. Except for the repair or replacement of parts within this regulation, any product sold by the company is still responsible for repairing the product without labor costs in order to protect the interests of the customer.

Follow us

Mobile station